The developed solution maximizes the work efficiency with error predictions, multi-linked optimized simulation, minimal human error, real-time equipment/facilities control, and real-time collaboration between the workshop and control center.

multi-service linkage of

Smart Factory on-site processes

-

STEP

01 -

Optimized simulation of multi-linkage

Commercialization and application based on our own technology

N-Way settings of input-output / Multiparameter model management / Process linkage framework, etc.

-

STEP

02 -

Approach by operating “automation optimized simulation” aiming for strategic importance (economic effect) and ease of execution (ease of technology) for companies requiring automation

-

STEP

03 -

Shifted to the development of SW components by utilizing the previously secured patent technology and introduced a method to reduce the development period and cost by reusing SW

(9 types of SW component products implemented for process site application)

Application Examples I

Supported flexibility of applicable models in simulation by implementing services according to multi-interface design for process linkage

Developed stable program for on-site user service through our own framework by wired and wireless networks

Developed N-way setting of input-output, multiparameter model management, and process linkage framework

9 types of SW component products implemented for process site application

Application Examples II

Collected big data through auto-collection of large data based on the material generated in the actual process

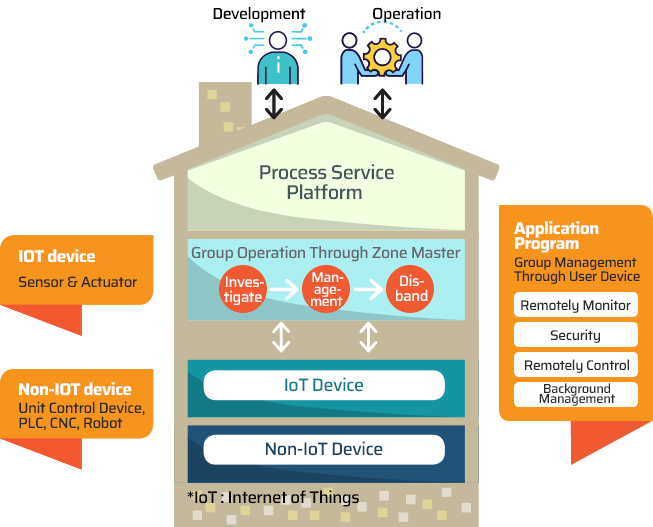

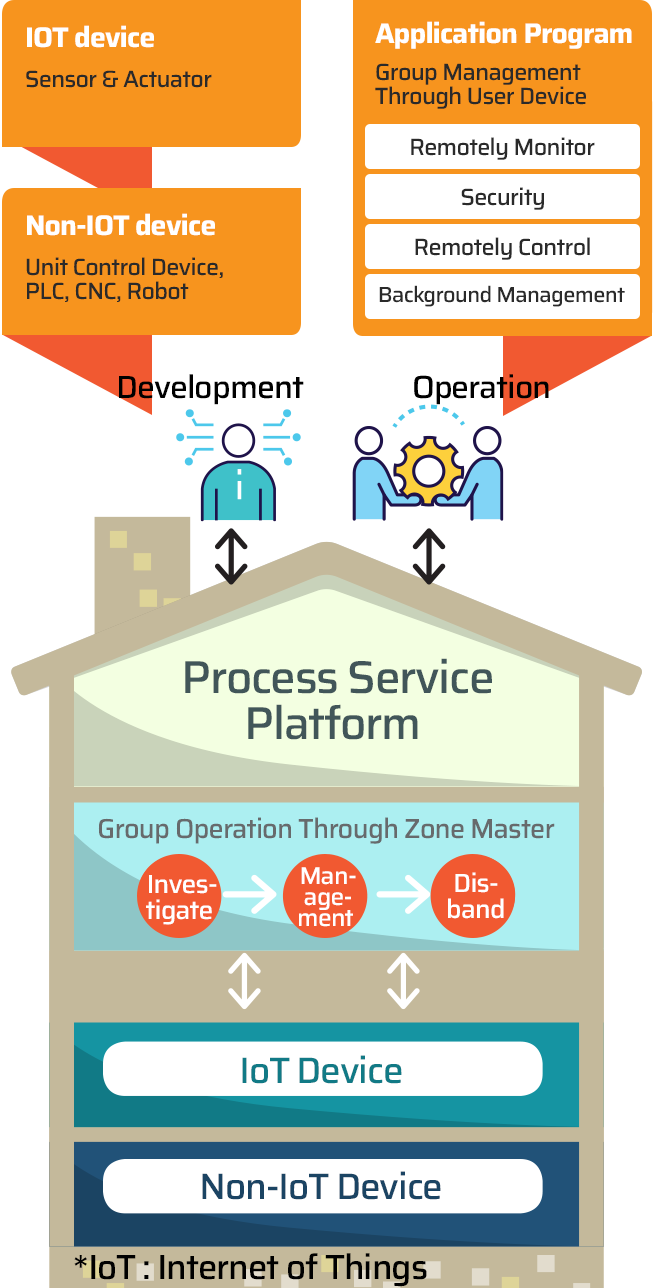

Group operation through Zone Master that self-develops various simulation situations and

problems that arises from linkage of existing sensors

Standardization and interoperability through development of technique application program

MR type visualization of UI/UX for implementation and application of industrial simulation and infortainment content services

Application Examples Ⅲ

Configuration of digital twin for Smart Factory Testbed

Smart Factory Testbed receives process status information through PLC and PIC UA standard protocol communication applied to each processes and visualizes it in 3D

Secures stability and expandability by developing Zone SW for OPC UA standard protocol communication between PLC and Zone Master

Provides customer-oriented optimization service by implementing individual components for data collection and visualization, data conversion, management and control condition by processes, and equipment/process status monitoring and visualization